Categories

Latest blog

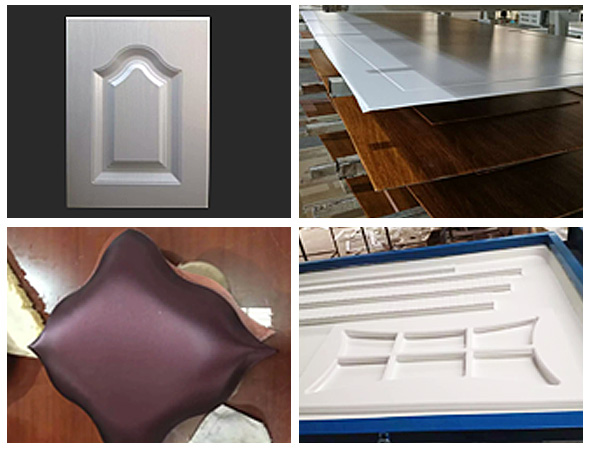

Water based polyurethane vacuum suction plastic adhesive application

Water based polyurethane vacuum suction plastic adhesive application

For water based polyurethane vaccum absorbing plastic adhesive ,we have many years for it with excllent adhesive and resin ,enjoying resitance to heat and low teperature curing.Kindly let me know your application and requirements we could help you as possible as we could

a.Phenomenon: large area of groove foam

Reason analysis:

1. The temperature or pressure did not meet the requirements, resulting in false suction;

2. Insufficient amount of glue, less spraying amount or glue infiltration of plate;

3. Insufficient preheating (softening PVC film) or blister time (molding time);

4. After blister molding, remove the pressure before the temperature drops.

5.The adhesive itself is not heat resistant enough.

Solution:

1. Increase the temperature or vacuum degree;

2. Increase sizing amount and select plates with good quality;

3. Increase preheating or molding time;

4. After blister molding, the temperature should be cooled to room temperature or slightly higher before the vacuum is removed.

5. Use with curing agent.

b.What you see: edges don't suck or shrink

Reason analysis:

1. When molding, the side temperature is low or vacuum degree is not enough; 2.

2. The temperature resistance of glue is not enough;

3. After blister molding, remove the pressure before the temperature drops.

Solution:

1. Increase the temperature or vacuum degree;

2. Use of curing agent;

3. After blister molding, the temperature should be cooled to room temperature or slightly higher before the vacuum is removed.

c.Phenomenon: blister out of the product surface pitting

Reason analysis:

1. The particle size of the glue is large, and the use of thin PVC film is easy to produce pitting, which is characterized by uniform dispersion; 2.

2. When used with curing agent, curing agent is not completely dispersed;

3. The surface of the plate is not cleaned, or after spraying glue, the dust in the workshop is large and sticks to it, and this kind of pitting point is scattered unevenly, and the size is different;

4. The viscosity of glue is too large, uneven dispersion;

5. The viscosity of glue is too small or the solid content is low, resulting in the plate furring, this kind of pitting point generally appears in the corner of the groove, into a block.

6. Air pressure of spray gun is not enough, and atomization is not good.

7. The glue is not filtered (in this case, if a bucket of glue is used until the end, if it falls into dirt or conjunctiva, filter it).

Solution:

1. Choose the glue with small particle size;

2. When adding curing agent, the mixing time should be prolonged so that the curing agent can be completely dispersed;

3. Clean the surface of the plate before spraying, and separate the spraying workshop;

4. Choose glue with appropriate viscosity or high solid content;

5. After the glue is dry, it can be polished with fine sandpaper;

6. Increase vacuum degree and adjust atomization effect;

7. When using, filter with a filter.

d.Phenomenon: local orange peel

Reason analysis:

1. Excessive spraying of local glue; 2.

2. There is grease on the surface of the plate, which causes shrinkage holes in the glue;

3. The curing agent is not completely dispersed, resulting in shrinkage cavity.

Solution:

1. Spray glue evenly;

2. Keep the surface of the plate clean;

3. Fully stir the curing agent to disperse evenly.

© Copyright: Anhui Dowell Huatai New Materials Co., Ltd All Rights Reserved.