Categories

Latest blog

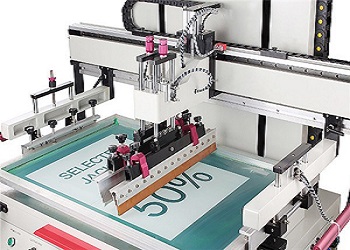

Water-based polyurethane resin for garment screen printing ink

In the field of silk screen printing, traditional inks made from oil-based materials have been widely used. However, they are not only non-recyclable but also release harmful pollutants into the environment. In recent years, waterborne polyurethane (WPU) inks have become an increasingly popular alternative due to their superior performance and environmental friendliness.

Water-based polyurethane resin(WBPUR) have been increasingly used in textile screen printing ink due to their excellent properties such as abrasion resistance, flexibility, and compatibility with various types of dyes and pigments. In this paper, we will discuss the technical features of WBPUR in textile screen printing inks, as well as its advantages over other resin types.

First, Water-based polyurethane binder is a versatile material that can be tailored to meet specific application requirements. The resin can be synthesized using different types of diols, such as polyester diols or polyether diols, to achieve different properties such as hydrophilicity or hydrophobicity. The molecular weight and molecular weight distribution of the resin can also be adjusted to improve its performance in different applications.

Second, the use of WBPUR in textile screen printing inks can improve the adhesion of the ink to the substrate, resulting in better color fastness and durability. The resin has excellent wetting properties, which allows it to form strong bonds with the substrate and resist peeling or cracking during printing. Additionally, the flexibility of WBPUR allows it to conform to the surface of the substrate without cracking or peeling.

Third, WBPUR has excellent compatibility with various types of dyes and pigments, making it an ideal choice for printing on various textiles such as cotton, linen, and silk. The resin can also be formulated with additives such as surfactants and thickeners to improve the rheological properties of the ink and enhance its printing properties.

In conclusion, the use of WBPUR in textile screen printing inks has several advantages over other resin types, including its versatility, excellent wetting properties, high abrasion resistance, and excellent compatibility with various types of dyes and pigments. These properties make WBPUR an attractive choice for the development of high-performance textile printing inks.

© Copyright: Anhui Dowell Huatai New Materials Co., Ltd All Rights Reserved.