Categories

Latest blog

Wide application with water-based polyurethane

Waterborne polyurethane appeared in the 1960s, after more than 40 years of development, has become an important material involving coatings, adhesives and various aspects of the national economy and people's life.Especially in the 21st century when environmental friendliness is gaining more and more popularity, water-based polyurethane is getting more and more attention.

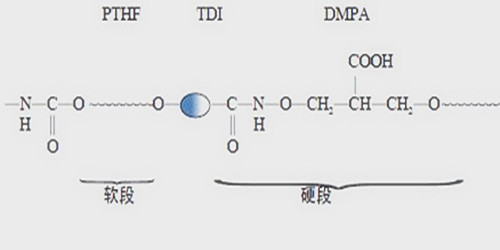

The structure of polyurethane has soft and hard segments, and the soft and hard segments can be adjusted.B. Excellent corrosion resistance, oil resistance, acid, alkali and salt resistance, industrial waste gas resistance;C. Wide range of construction temperature, from low temperature to room temperature to heat curing temperature;D. Excellent electrical properties;E. Good mixing performance with a variety of resins;F. Good decoration and protection performance;G. High temperature resistance, -40 ~ 300℃ have the corresponding varieties.

However, solvent-based polyurethane materials contain toxic solvents, which seriously pollute the environment and endanger human health.With the improvement of the quality of human life and the increasingly strict environmental regulations, various environmental protection regulations have strict limits on the emission of volatile organic compounds and the content of harmful solvents.Water-borne polyurethane, with water as its dispersion medium, is not only non-toxic, not easy to burn, not polluting the environment, energy saving, safe and reliable, but also has some important performance characteristics of solvent polyurethane.Waterborne polyurethane maintains the performance of organic solvent based products on the premise of basically not changing the use process of organic solvent based products, and features such as low cost, safe transportation and good working environment. Therefore, waterborne polyurethane materials are rapidly developing waterborne materials in recent years.

In waterborne polyurethane, the addition of water is not our ultimate purpose. Water is only a dispersion medium, which can disperse solid polyurethane into liquid for construction.What we need finally is the polymer material after the water evaporates.Waterborne polyurethane is widely used as coatings and adhesives.When the dispersion is applied on a single interface, the film obtained after drying is the coating, while when it is applied on two interfaces, the dried polyurethane material glued the two interfaces together is the adhesive.Coatings and adhesives are two containing a very broad concept, a lot of daily not called coatings and adhesives in the field or essentially belong to the category of coatings adhesives.The properties of waterborne polyurethane are so excellent and changeable that its application field can cover almost all application fields of coating adhesives.Waterborne polyurethane is too widely and complex to be used.

1. Soft materials coating

Soft base coating is not usually called coating, almost all natural leather needs polymer coating, we call it leather coating.Unpainted leather is not waterproof and its appearance is extremely grey.Waterborne polyurethane has become the main product of leather finishing due to its excellent flexibility.

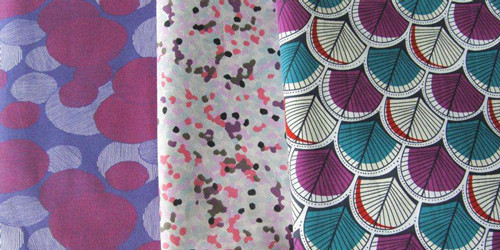

30% of textiles are finished with a coating that gives the finished fabric a better look and feel, changing the fabric's function.Coated fabrics are widely used in clothing (such as coated fabrics can prevent feather from being thrown over, and almost all fabrics of feather products are coated), curtains, tents, etc. Waterborne polyurethane, with its good performance, is for the development direction of fabric coating.

2. Hard materials coating

Waterborne waterborne polyurethane is the mainstream product of waterborne wood paint in the future.Waterborne polyurethane can also be used for building coatings, metal coatings, plastic coatings, ceramic coatings, glass coatings.

3. lamination of materials

Packaging materials composite (aluminum - plastic composite, paper - plastic composite, plastic - plastic composite), fiber composite materials.

4. Textile finishing and printing

The formation of coating on the surface of synthetic or natural fabric fibers can change the properties of the fiber fabric, such as natural wool due to the scale structure on the surface, in the fabric so that the fiber can only one-way slide, which is the reason why wool and some natural fabrics shrink.Waterborne polyurethane can be used to form an extremely thin coating on the surface of wool fiber, covering the fiber scales, so that the fiber can achieve anti-shrinkage effect.Polyurethane can be used as an adhesive to bond granular pigment to fibrous fabrics, which is currently the most widely used pigment printing.

For any requirements on water based polyurethane resin and adhesive ,kindly contact us !

© Copyright: Anhui Dowell Huatai New Materials Co., Ltd All Rights Reserved.